Henan Lantian Machinery Manufacturing Co., Ltd.>News>Company news>charcoal briquette dryer

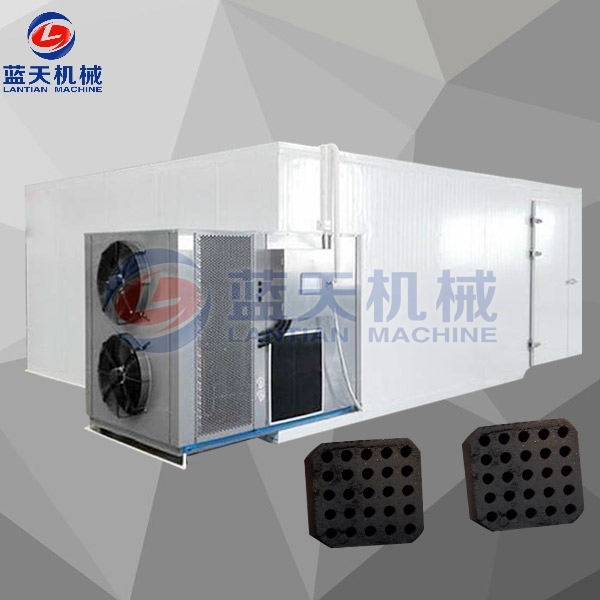

Henan Lantian Machinery Manufacturing Co., Ltd.>News>Company news>charcoal briquette dryerThe production of charcoal briquette is faced with drying problems. Without adequate drying, high water content is easy to cause moldy deterioration, low combustion efficiency and heavy smoke. Natural drying efficiency is low, restricted by weather, and traditional drying equipment is difficult to accurately control temperature, which is easy to cause dry cracking and deformation. In order to meet the needs of large-scale production of charcoal briquette and ensure product quality, many manufacturers choose our charcoal briquette dryer.

According to the raw material characteristics of charcoal briquette, initial water content and expected final dryness, the operator can conveniently set the drying parameters on the PLC control panel to avoid carbonization and cracking of charcoal briquette caused by too high temperature, or incomplete drying caused by too low temperature. The unique circulation air path design further improves drying efficiency and quality, reduces heat loss, accelerates water evaporation, and ensures uniform product heating.

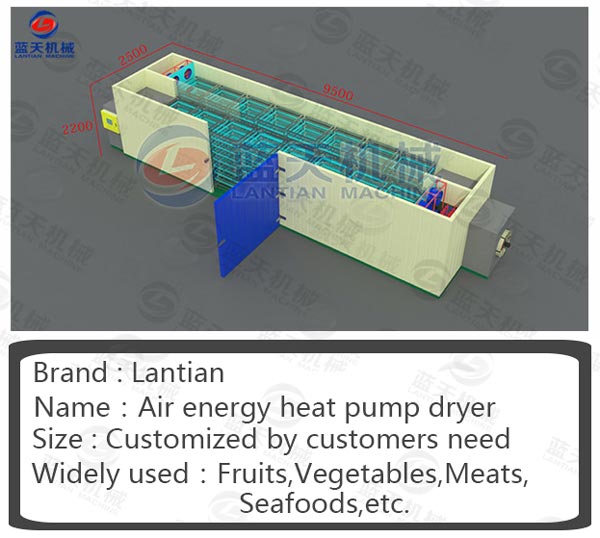

Our dryers also adopt the working mode based on the inverse Carnot principle, which greatly improves the energy utilization efficiency and reduces the energy consumption, which is in line with the current development trend of energy conservation and environmental protection.If you need a dryer, please leave a message to us, our staff will reply to you as soon as possible.

Last:Shisha charcoal tablet machine improves the carbon quality of shisha with precision technology

Next:Wood carbonization furnaces enable wood processing to transition to high value-added