Detailed introduction

Machines description

In order can recycle use limited biomass materials, our Lantian technical team have produced series briquette machine, one of is sugarcane bagasse pellet machine, this machine can extrude materials into small particle at a certain temperature and pressure, finished products have high hardness, our bagasse pellet machine price is just and operation is simple, if you need, Lantian is a good choice for you.

Working principle

Our bagasse pellet machine is consists of main engine, feeding port, die, screen mesh, discharge port and retarder. When sugarcane bagasse pellet machine is working, after the power supply is connected, the inner belt pulley is driven by the motor under the drive of the reducer, and the power generated is transmitted to the rotating shaft, the gear and the rotating shaft move synchronously to extrude bagasse powder into small particles.

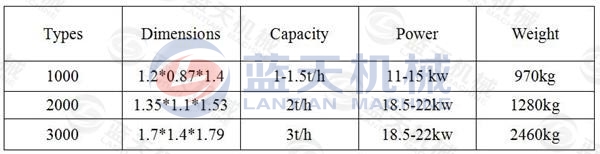

Parameter of

Machines features or details

1.The density before extrusion is generally about 0.6-0.8, and the density of particles after extrusion is more than 1.1, which is convenient for storage and transportation.

2.It can be used as combustion material to reduce air pollution caused by combustion.

3.Screen mesh is easy to install and disassemble, and and also can adjust tightness.

4.The dies are made of high quality metal raw materials, the single diameter of the die is 4-12 mm.

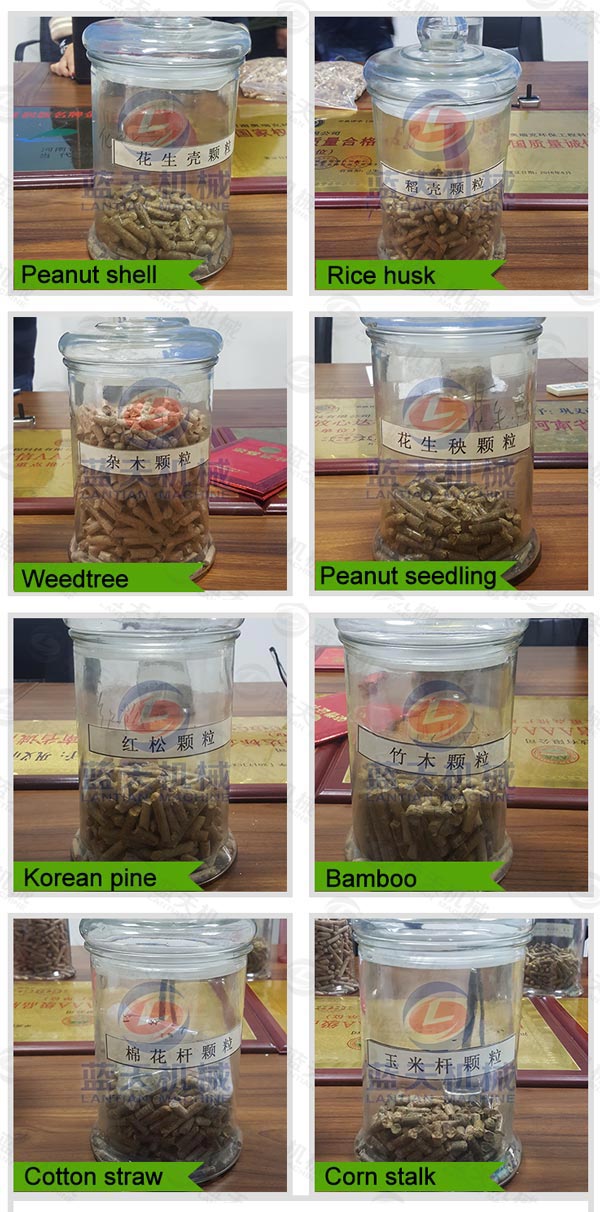

Finished products display

Product line

1.First, bagasse need crush into finer powder by crusher machine.

2.Crushed bagasse powder need drying out excess water by bagasse dryer machine.

3.Dried bagasse powder will be transfer to bagasse pellet machine for extruding, and finished products have high hardness and high density, and east to store.

Production line

The sugarcane bagasse pellet machine have good extruding effect, and bagasse pellet machine price is reasonable, and machines are have ISO and CE certification, if you need bagasse pellet machine, you can send us inquiry, we will reply you as soon as possible.

Henan Lantian Machinery Manufacturing Co., Ltd.>Products>Biomass Pellet Machine>Sugarcane Bagasse Pellet Machine

Henan Lantian Machinery Manufacturing Co., Ltd.>Products>Biomass Pellet Machine>Sugarcane Bagasse Pellet Machine