Detailed introduction

Machines description

Our Lantian Technical team have produced series high quality and stable performance tailings ball press machine, pretreated materials can be pressed by tailings coal ball press machine into ball shape, machine have high quality and simple operation, and finished products have high hardness and good burning effect.

Working principle

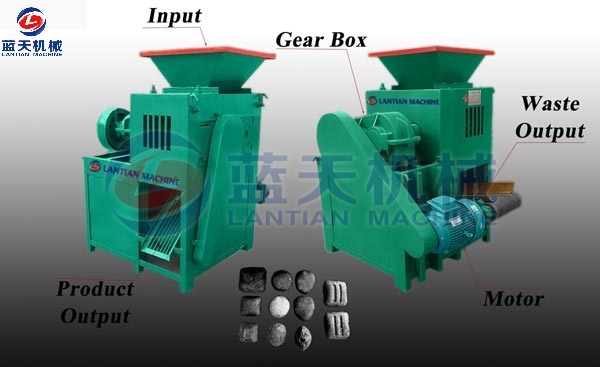

Our tailings ball press machine is mainly composed main engine, conveyor belt, input, dies, output, gear box, motor and waste output. When machine is working, pretreated materials will transfer to input and pressed by both sides of the die. Our tailings coal ball press machine for sale to overseas received widely praise because our machine have high quality and simple operation, if you need this machine, Lantian is worthy your trust.

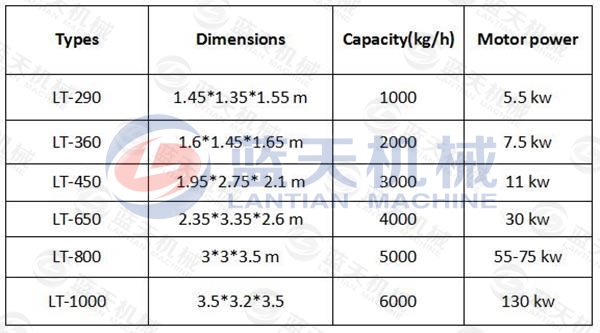

Parameter

Finished product display

Machine Characteristics

1. Our tailings coal ball press machine is suitable for various powdered raw materials.

2. Dies can be customized and changed, and material adopted #65 manganese steel, not easy to damage.

3. Materials are pressed by a pair of rollers, finished products are high density, high strength and high hardness.

Customers site

Our tailings ball press machine have ISO and CE certification, it is easy to use and maintain, our tailings coal ball press machine for sale to many countries are received unanimous praise, if you need, Lantian is a good choice for you.

Production process

Before pressing, materials need a series of processing

1.Firstly, tailings need carbonized by carbonization furnace

2.Carbonized materials need crushed into finer powder, and then they will be transferred to automatic weighing system to add adhesive and stirred evenly in binder mixer.

3.Mixed powder will be transferred to tailings coal ball press machine for better briquetting.

4.Pressed materials can drying out excess water by dryer machine.

5.Dried products can use our briquette packaging machine for packaging or better storage.

Henan Lantian Machinery Manufacturing Co., Ltd.>Products>BBQ Briquette Equipment>Tailings Ball Press Machine

Henan Lantian Machinery Manufacturing Co., Ltd.>Products>BBQ Briquette Equipment>Tailings Ball Press Machine